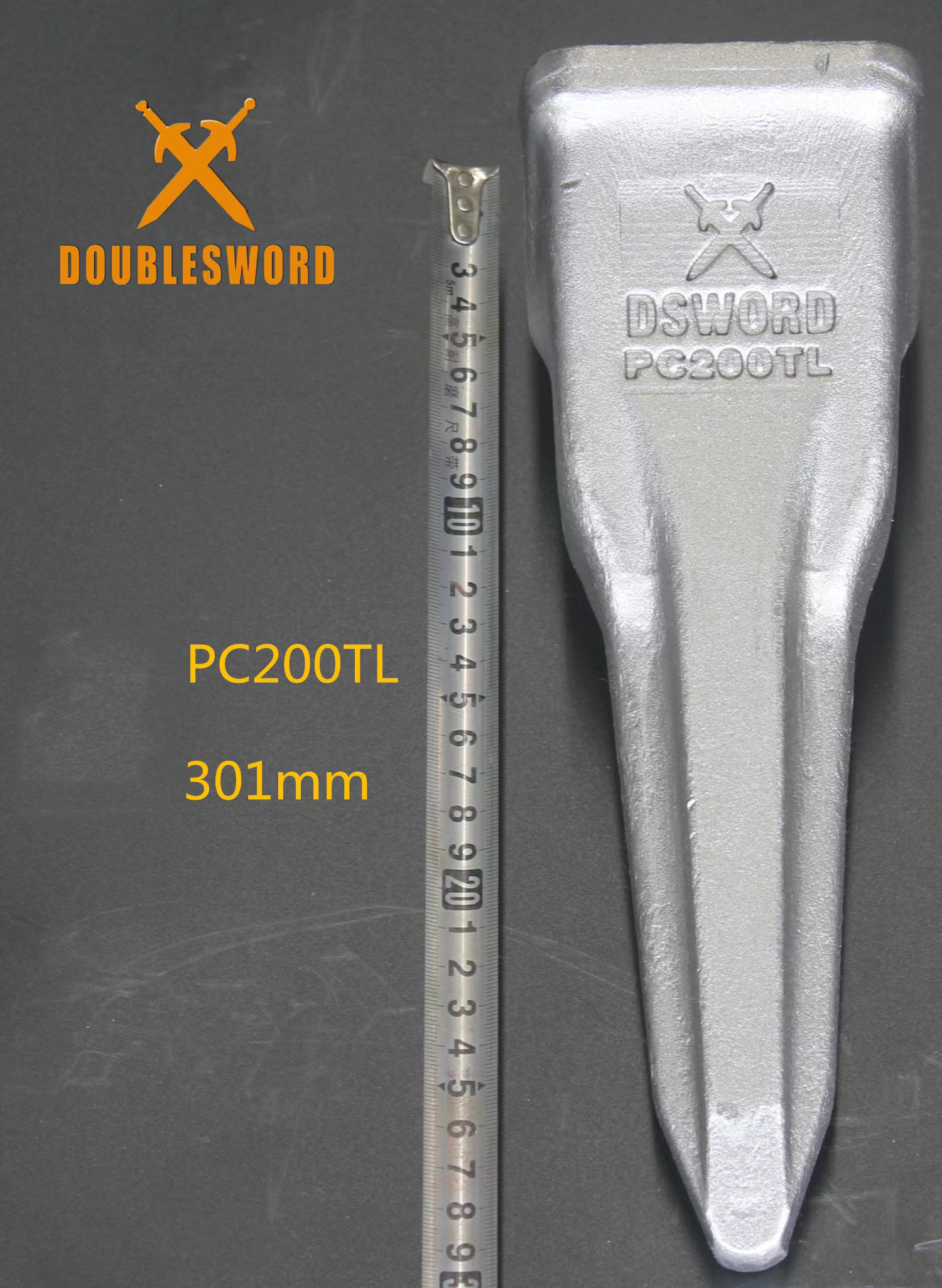

Bucket earning forming method (kayan aikin haƙori na bokitin haƙori)Farashin haƙora na Bokiti

Tsarin ƙirƙirar haƙori da jefa haƙori a bokiti:

Ƙirƙira: Ana samunsa ne ta hanyar fitar da shi a ƙarƙashin yanayin zafi mai yawa. Yana iya tace ƙwayoyin da ke cikin sassan, tare da yawan aiki da kuma gurɓataccen muhalli. Ba zai haifar da gurɓataccen muhalli ba.

Siminti: Karfe mai narkewa yana cika mold ɗin don sanyaya. Yana da sauƙin samun porosity a tsakiyar aikin. Tsarin samarwa zai haifar da gurɓataccen muhalli mai tsanani.

Haƙoran ƙera bokiti suna amfani da injinan ƙera don yin matsin lamba akan wasu barguna na ƙarfe na musamman, fitar da su a yanayin zafi mai yawa, tsaftace kayan lu'ulu'u a cikin ƙera, kuma su zama nakasa ta filastik don samun wasu kaddarorin ƙera. Bayan ƙera, ƙarfen zai iya inganta tsarinsa, wanda zai iya tabbatar da cewa haƙoran ƙera bokiti suna da kyawawan halayen ƙera, juriya ga lalacewa, da tsawon rai na sabis. ...

Haƙoran bokiti galibi ana raba su zuwa haƙoran bokiti da haƙoran bokiti bisa ga hanyoyin ƙera su. Aikin hanyoyin ƙera guda biyu ya bambanta. Gabaɗaya, haƙoran bokiti na jabu sun fi jure lalacewa, sun fi wahala, kuma suna da tsawon rai, wanda ya ninka na haƙoran bokitin da aka yi da siminti, amma farashin sau 1.5 ne kawai. Haƙoran bokiti muhimman sassan haƙora da forklifts ne. A zamanin yau, ana amfani da haƙoran bokiti na jabu sosai. Ana fitar da haƙoran bokiti na jabu ta hanyar mashin ɗin hydraulic na jabu (mashin ɗin hydraulic na jabu mai zafi, mashin ɗin mai na jabu mai zafi) ta cikin mashin ɗin.

Mashin ɗin yin haƙori na bokiti (kayan aikin yin haƙori na bokitin haƙori) yana amfani da fasahar sarrafa daidaiton lantarki da ruwa don cimma ikon sarrafa matsi na dijital, gudu da bugun jini, kuma yana iya sarrafa girman yin haƙori daidai. Yana ɗaukar tsarin firam ɗin kafada mai kyau tare da kwanciyar hankali gabaɗaya. Duk silinda masu mai silinda ne na plunger, kuma benchin aiki na hannu yana da karko a cikin juyawa, tare da na'urar buffer. Kayan aikin kuma ya dace da yin haƙori na sanyi da zafi na ƙarfe, da kuma tsarin matsi na kayan filastik. Yana iya kammala yin haƙori kyauta, yin haƙori da sauran hanyoyin.

Matakan tsari mai zafi na haƙoran haƙoran haƙoran haƙoran haƙoran haƙora:

Mataki na 1: Tsarin yin amfani da faifan faifan yana amfani da faifan faifan daidaitacce, kuma juriyar faifan faifan shine ± 0.5mm.

Mataki na 2: Tsarin dumama yana amfani da dumama matsakaiciyar mitar induction a 1150 ℃ don dumama saman aikin da sauri da rage samuwar sikelin oxide.

Mataki na 3: A cikin tsarin damuwa, cire fatar oxide da ke kewaye da abin da ba ya haifar da matsala, kuma a lokaci guda cire fatar oxide ta sama da ta ƙasa da iska ta hura iska, don inganta ingancin saman kayan da aka yi da kuma tsawon lokacin sabis na ma'aunin, kuma tabbatar da cewa rabon tsawon da ba ya canzawa zuwa diamita bai wuce 2.5 ba yayin da ake tayar da hankali.

Mataki na 4: A cikin tsarin rufewar mahaɗin fitar da haƙori, mashin ɗin sama yana motsawa tare da toshe mai zamiya na mashin ɗin fitar da haƙori na bokiti (kayan aikin haƙori na tono haƙori) don matse wurin da babu komai har sai dukkan ramuka sun cika da ƙarfe. Haƙorin bokitin da babu komai yana samuwa ta hanyar fitar da mahaɗin zamiya na saman mashin ɗin a cikin mold. Toshin zamiya na mashin ɗin yana dawowa, yana fitar da sassan fitar da haƙori da aka samar, kuma an kammala duk hanyoyin fitar da haƙori. Farashin haƙori na bokiti

Tsarin musamman na ƙirƙirar haƙoran bokiti:

Ana dumama ƙarfe mai zagaye zuwa zafin da ake buƙata don yin ƙira bayan an gama gogewa bisa ga girmansa, sannan a sanya shi a kwance a cikin ramin da aka riga aka ƙirƙira don yin ƙira sannan a juya shi zuwa digiri 90 don sake yin ƙira. Ramin da aka riga aka ƙirƙira yana da faɗi tare da kauri ɗaya kuma ƙarshensa ɗaya siriri. Siraran ƙarshen ɓoyayyen da aka riga aka ƙirƙira ana sanya shi a tsaye ƙasa a cikin ramin da aka riga aka ƙirƙira. Ƙarfin ƙwanƙwasa yana rabewa kuma yana fitar da ɓoyayyen zuwa ƙasa. Bayan sau 4 zuwa 5 na yin ƙira, ana samar da ɓoyayyen da aka riga aka ƙirƙira ya zama ɓoyayyen da aka ƙirƙira, Sannan, ana yin injin ɗin ɓoyayyen da aka ƙirƙira kuma ana yi masa magani da zafi. Ana sarrafa ɓoyayyen zuwa siffar ɓoyayyen da ta yi kama da siffar ɓoyayyen da aka riga aka ƙirƙira. Sannan, ana samar da rami a tushen ɓoyayyen da aka riga aka ƙirƙira ta hanyar raba da fitar da tushen ɓoyayyen da aka ɗora a lokacin ɓoyayyen. Tasirin ƙirƙirar yana da kyau, rushewa yana da sauƙi, kuma ingancin sarrafawa yana da girma. Bugu da ƙari, aikin injiniya na haƙorin bokiti ya fi samfuran da aka sarrafa ta hanyar ɓoyayyen. Ta hanyar inganta ramin da aka riga aka ƙirƙira da kuma ramin da aka ƙirƙira na ƙarshe, izinin injin yana da ƙanƙanta kuma farashin sarrafawa yana da ƙasa, ƙarancin amfani da makamashi, babu gurɓataccen muhalli.

Lokacin Saƙo: Nuwamba-28-2022